Plate Heat Exchangers Working Principle

PLATE HEAT EXCHANGER WORKING PRINCIPLE

Heat Exchangers

Plate Heat Exchangers were first produced in the 1920s and have since been widely used in a great number of sectors.

A plate exchanger consists of a series of parallel plates that are placed one above the other so as to allow the formation of a series of channels for fluids to flow between them.

The space between two adjacent plates forms the channel in which the fluid flows.

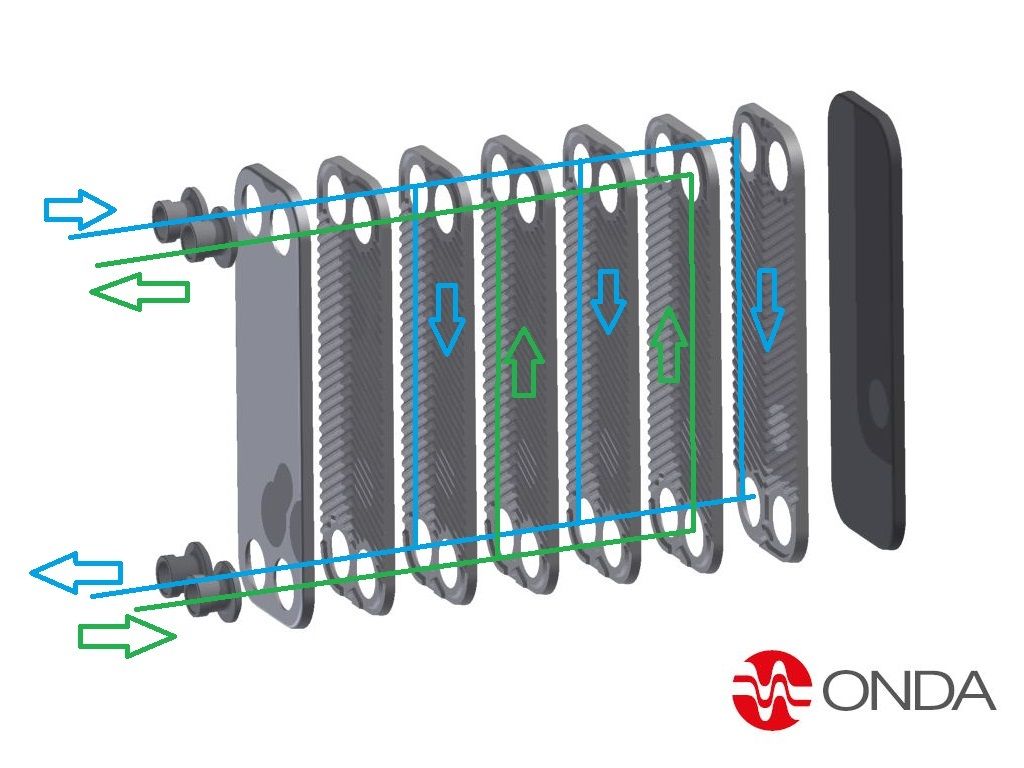

Inlet and outlet holes at the corners of the plates allow hot and cold fluids through alternating channels in the exchanger so that a plate is always in contact on one side with the hot fluid and the other with the cold.

The size of a plate can range from a few square centimeters (100 mm x 300 mm side) up to 2 or 3 square meters (1000 mm x 2500 mm side). The number of plates in a single exchanger ranges from just ten to several hundred, so reaching surface exchange areas up to thousands of square meters.

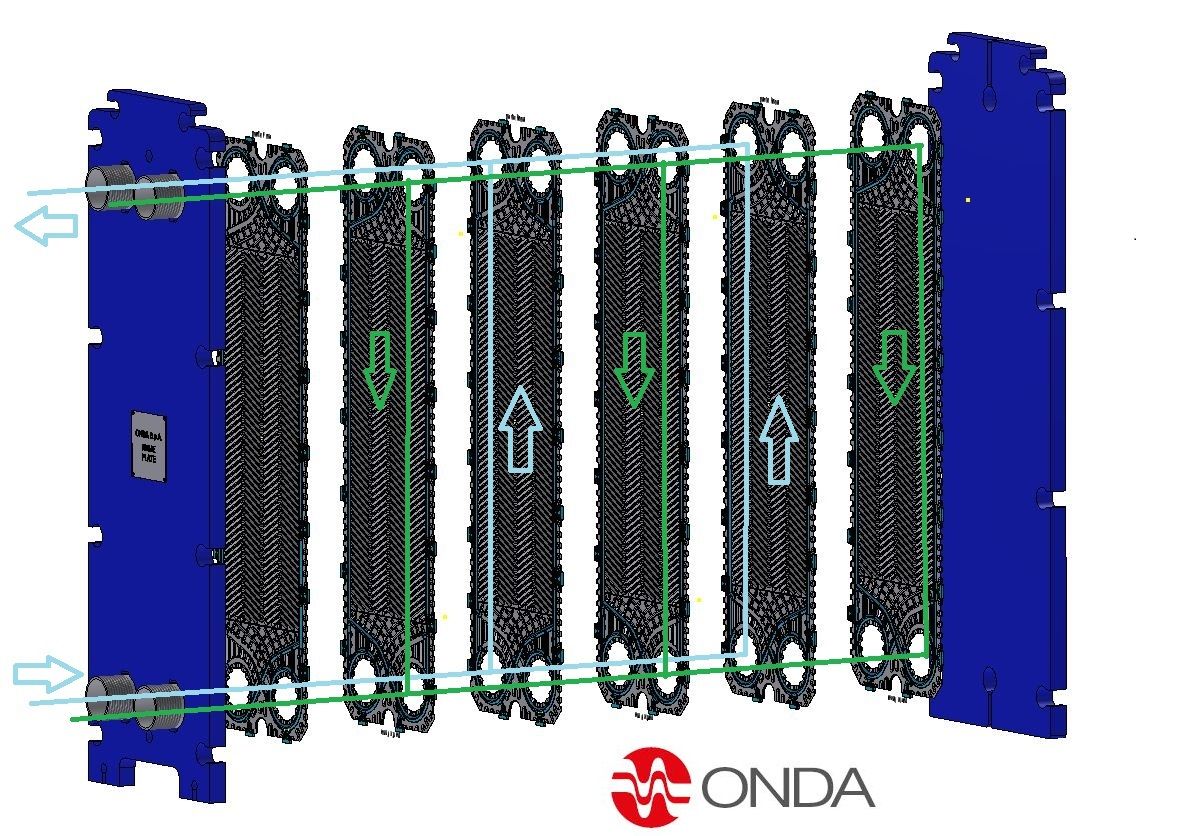

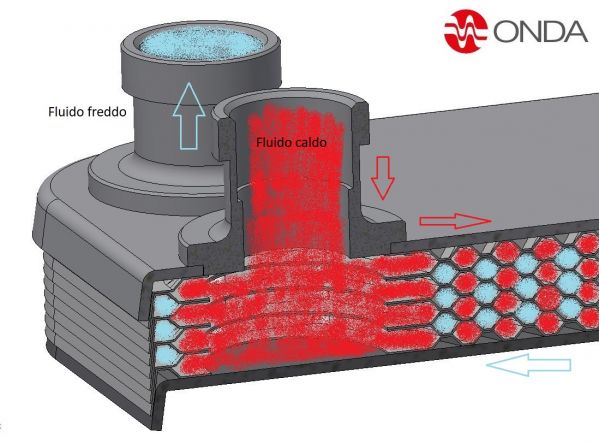

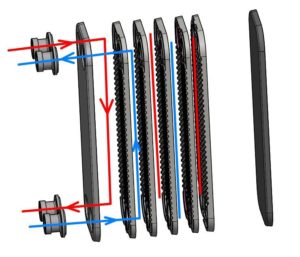

The figure shows the flow of fluids inside the exchanger. Fluids are divided into several parallel streams and can produce a perfect countercurrent.

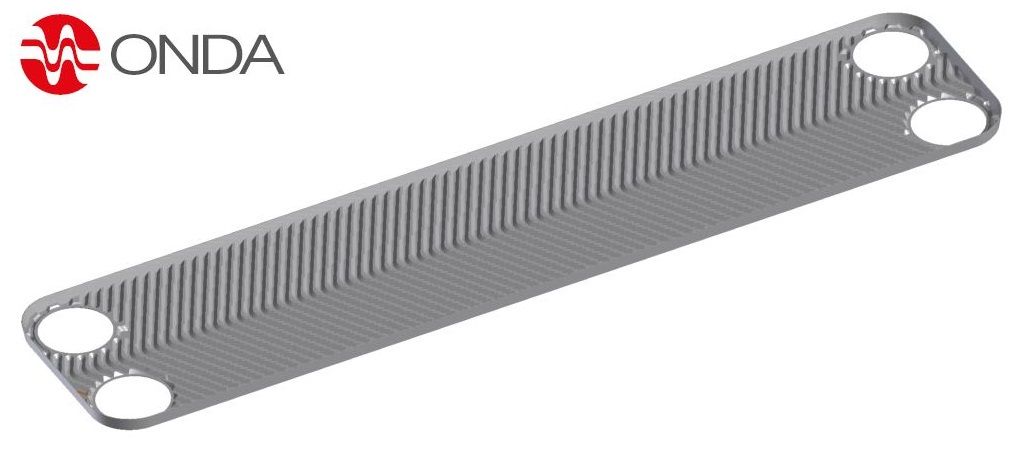

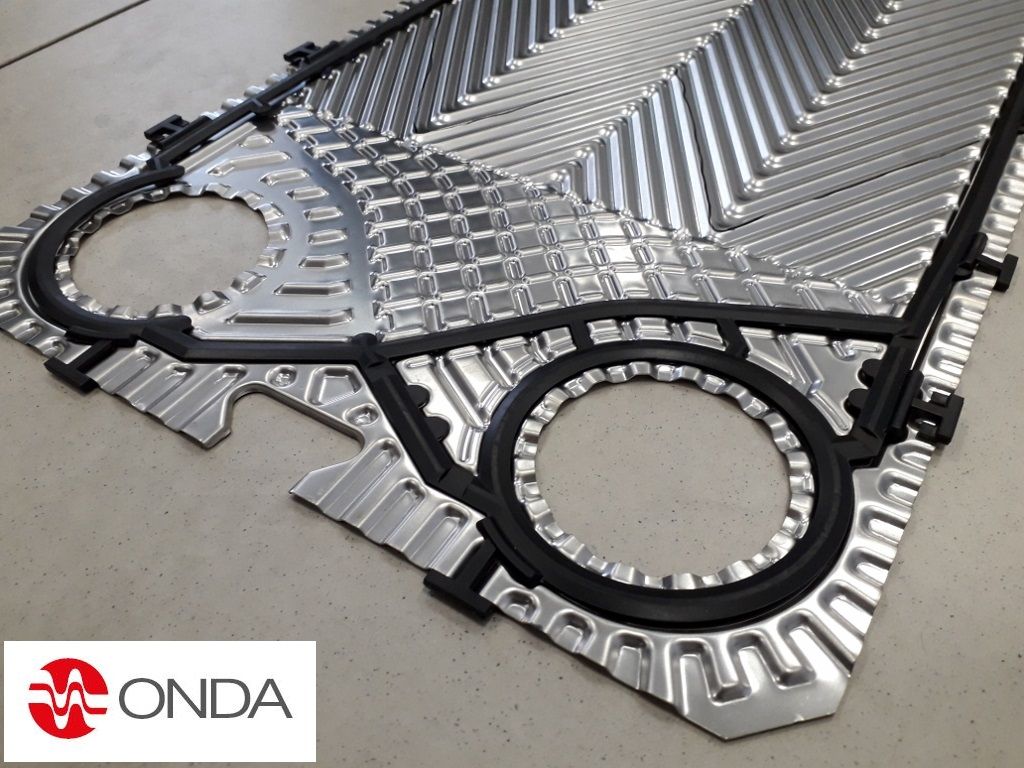

Generally, these plates are corrugated in order to increase the turbulence, the thermal exchange surface and to provide mechanical rigidity to the exchanger. Corrugation is achieved by cold forging of sheet metal with thicknesses of 0.3mm to 1 mm.

The most frequently used materials for the plates are stainless steel (AISI 304, 316), titanium and aluminium.

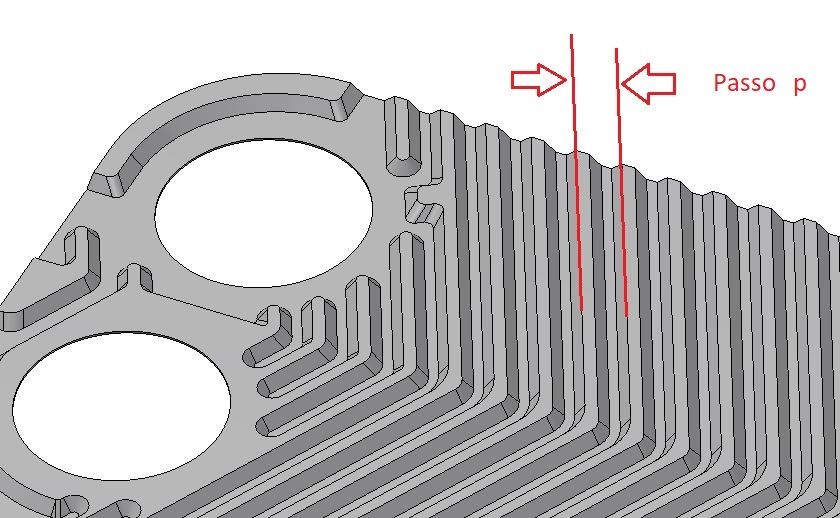

The corrugation on the plates forces the fluid on a tortuous path, setting a space between two adjacent plates b, from 1 to 5 millimeters.

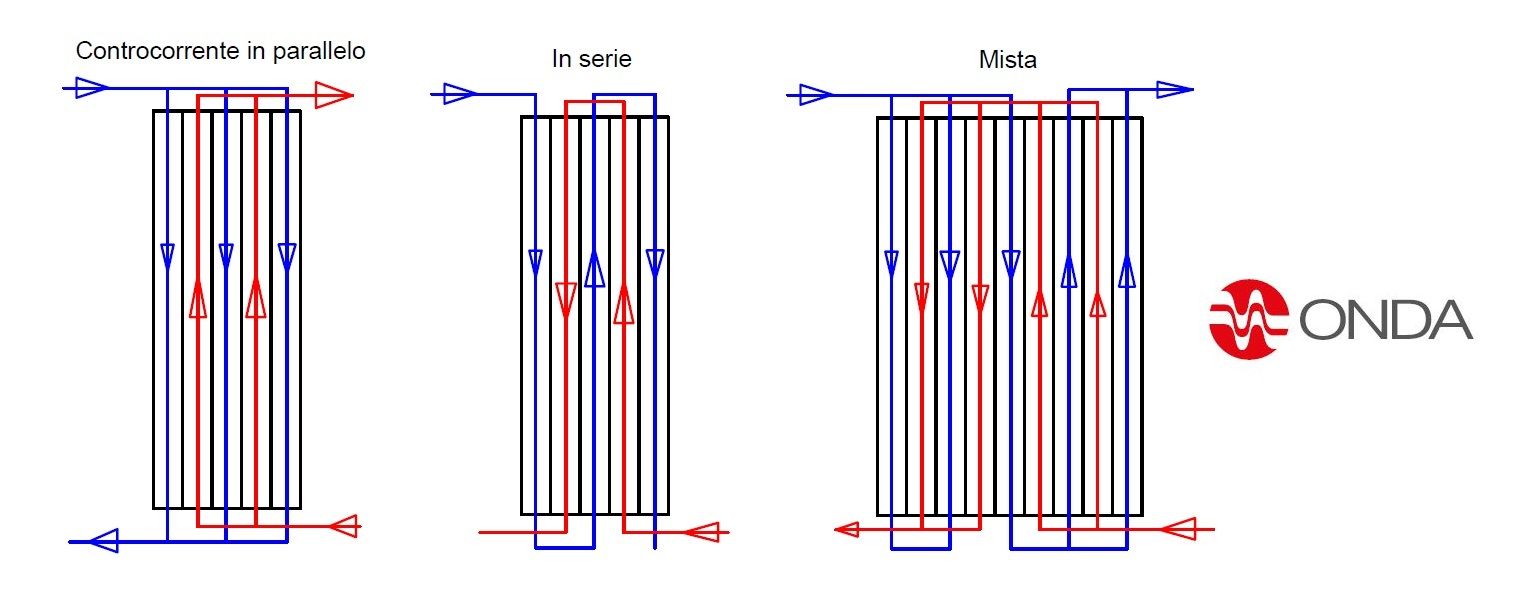

The fluids can cross the channels in series (a less common solution) or in parallel by making counter-current or current configurations.

The serial configuration is used when there is a small flow rate for each fluid but high heat jump; the greatest problem is with a high pressure drop and an imperfect counter-current.

The parallel configuration with countercurrent channels is used for high flow rates with moderate temperature drops, and is the most widely used.

When there is a great difference between the flow rates (or between the maximum permissible pressure drop) of the two fluids, the exchanger can run twice by the fluid with a lower flow (or higher losses) to balance the values of pressure drops or specific flow rates in the channels.

The figure shows the different configurations: in parallel, in series and mixed

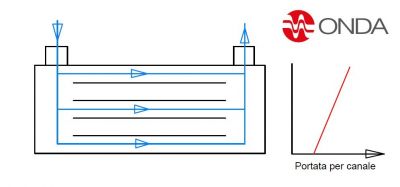

One of the most common problems for plate heat exchangers is an irregular supply of the all channels in parallel. In fact, the fluid tends to distribute in greater quantities in the first channels rather than the last ones in order to balance the pressure drop.

As the number of plates increases, even distribution declines, resulting in a decrease in the overall performance of the exchanger.

There are two basic types of plate heat exchangers: BPHE-Brazed Plate Heat Exchangers and PHE-Plate Heat Exchangers.

Plate and Frame Heat Exchangers

In the PHE the plates create a frame where the plates are pressed with headers and tie bars, and the seal is guaranteed by gaskets. Gaskets, in addition to their sealing effect, serve to direct the flow of the fluids, and are placed along the grooves at the edges of the plates.

The maximum temperatures used for sealing heat exchangers are between 80°C and 200°C while pressures can reach 25 bar.

Gaskets are available in various types of butyl or silicone rubber.

The main characteristics of these types of heat exchangers are:

- quick and easy dismantling for cleaning and control operations

- adaptation to variable operating conditions by adding or removing heat plates to modify the installed thermal flow

- any fluid leaks due to non-perfect sealing of the gaskets do not contaminate the other fluid but are directed away

- materials that are poorly adapted to soldering, such as titanium, may be used

- the gaskets limit the maximum pressure and temperature values

- potentially high costs due to the design of moulds, presses and all the production process

- high cost of the gaskets

Brazed Plate Heat Exchangers

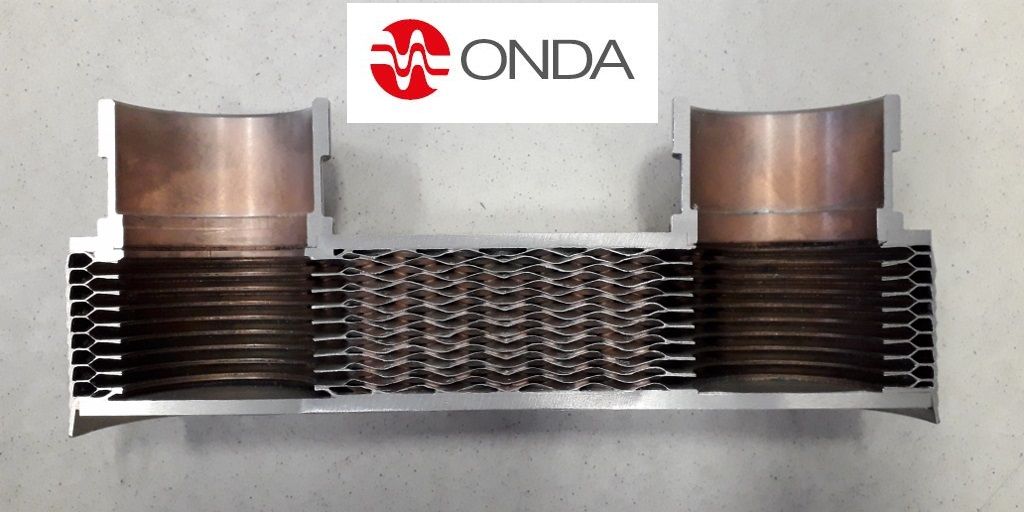

Brazed plate heat exchangers have no headers, tie bars or sealing gaskets because the plates are furnace brazed at temperatures of 1100°C.

During the assembly phase, a sheet of brazing material (generally copper but also nickel) is placed between the plates, the pack is pressed and subsequently baked for some hours.

The BPHE exchanger is more compact, lighter and less bulky than one with gaskets.

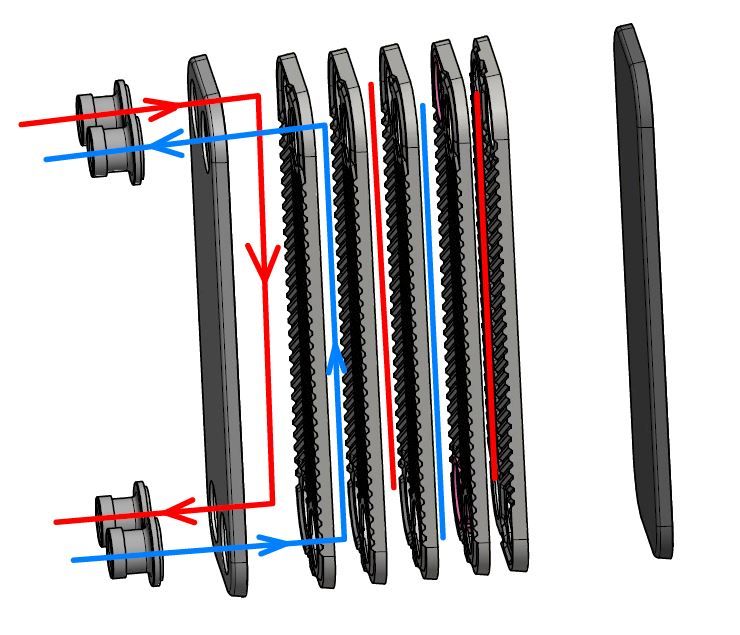

The image shows the path made by the hot and cold fluid.

The brazing material carries out the function both of the gaskets and the frame.

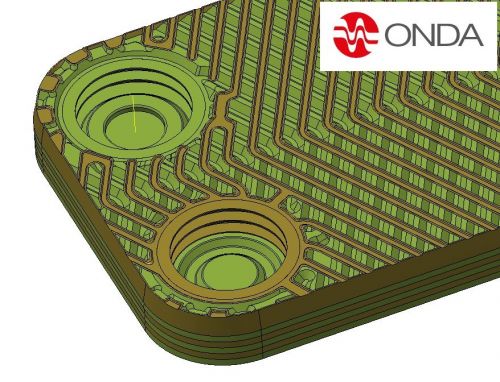

These exchangers are generally used with chevron corrugated plates, which are assembled alternating the corrugation directions in order to create a lattice contact.

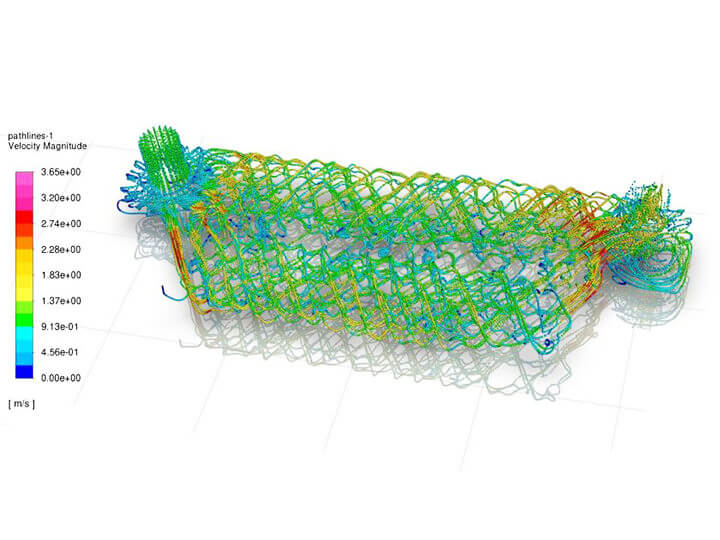

The crossing points between the corrugations of two coupled plates form a dense network of contact points that confer pressure tightness and induce swirling streams that improve heat exchange.

In this way, the turbulence of the fluids is high even at low nominal input speeds and the flow passes from laminar to turbulent for low flow rates.

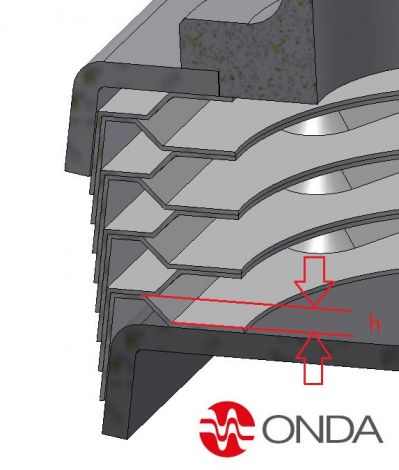

The figure shows a cross section of an exchanger with 8 plates in total (6 of which are useful for heat exchange) in which the 3 channels used for the passage of the refrigerant fluid (in light blue) and the 4 for water (in red) are seen.

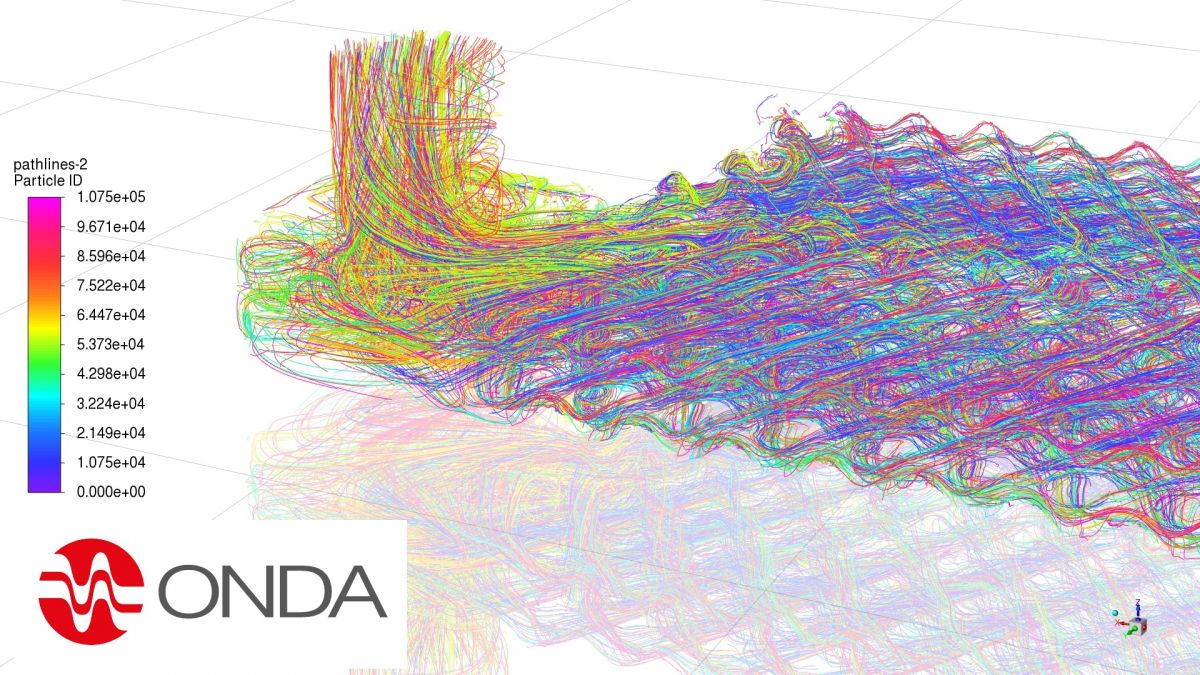

It is immediately noticeable that the path made by the fluids is chaotic, in fact, the cross section varies continuously.

The main disadvantage of these exchangers is that they are not removable and so maintenance and cleaning are not possible or at least difficult, and no flexibility exists as the number of plates can in no way be varied.

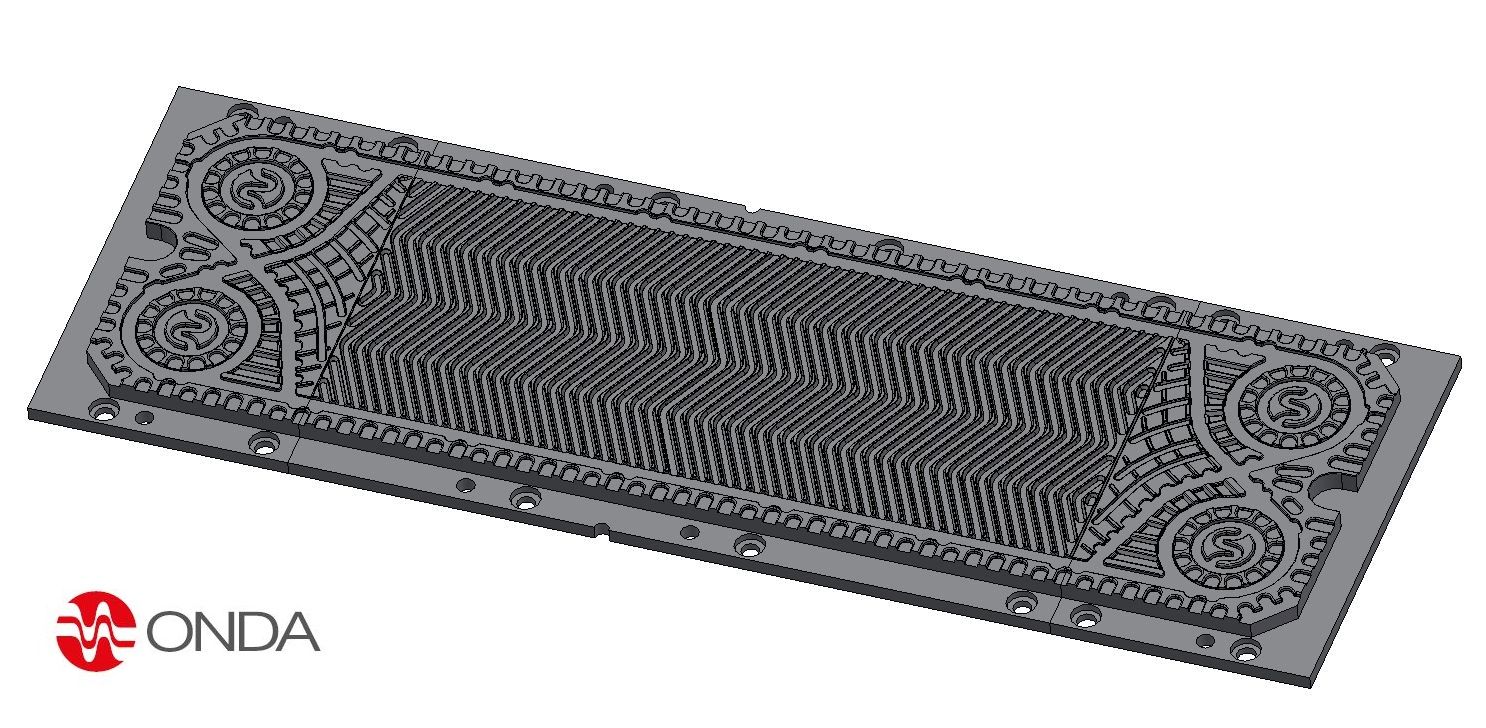

The surface of the plates is corrugated in order to increase the turbulence of the fluid during the flow into the channels.

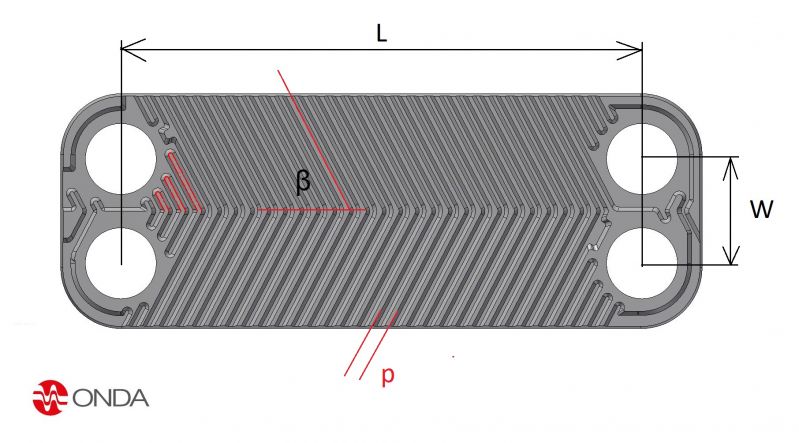

The figure highlights the main geometrical parameters of the corrugation:

Corrugation pitch p; corrugation height b and chevron angle β compared to the main direction of the flow.

The inclination of the plate corrugations has a determining effect on thermal exchange and load losses. In fact, a pair of plates with a high β angle (> 45 °) gives a turbulence and therefore a high heat exchange with a higher pressure drop.

A smaller angle (β <45 °) causes a lower turbulence flow and lower heat exchange coefficients but also lower pressure drops.

The search for a compromising β angle between high exchange coefficients and acceptable load losses is therefore essential.

The corrugation height b has an important effect on the exchange coefficients because a greater depth causes greater turbulence.

These two picture below show an Wieland Onda case study of the flow inside the channel of a braze plate heat exchanger, you can see the flow going inside the channel in and out of the BPHE

The height and pitch of the corrugations increase the plate exchange surface area: the surface enlargement factor φ is defined as:

Φ = actual corrugated surface area / projection area corrugated surface

The actual area is difficult to compute, so in order to compare different exchangers, reference is made to the projected area.

It should be kept in mind that heat exchangers with the same projected area (ie plates of the same size) may have different effective areas depending on the value of the surface enlargement factor φ.

The ratio between the plate length L and the plate width W also affects performance but to a lesser degree than other variables. In general, a high ratio between plate length and width gives high exchange rates but higher load losses.

Enrico Golin, R&D Wieland Onda Srl

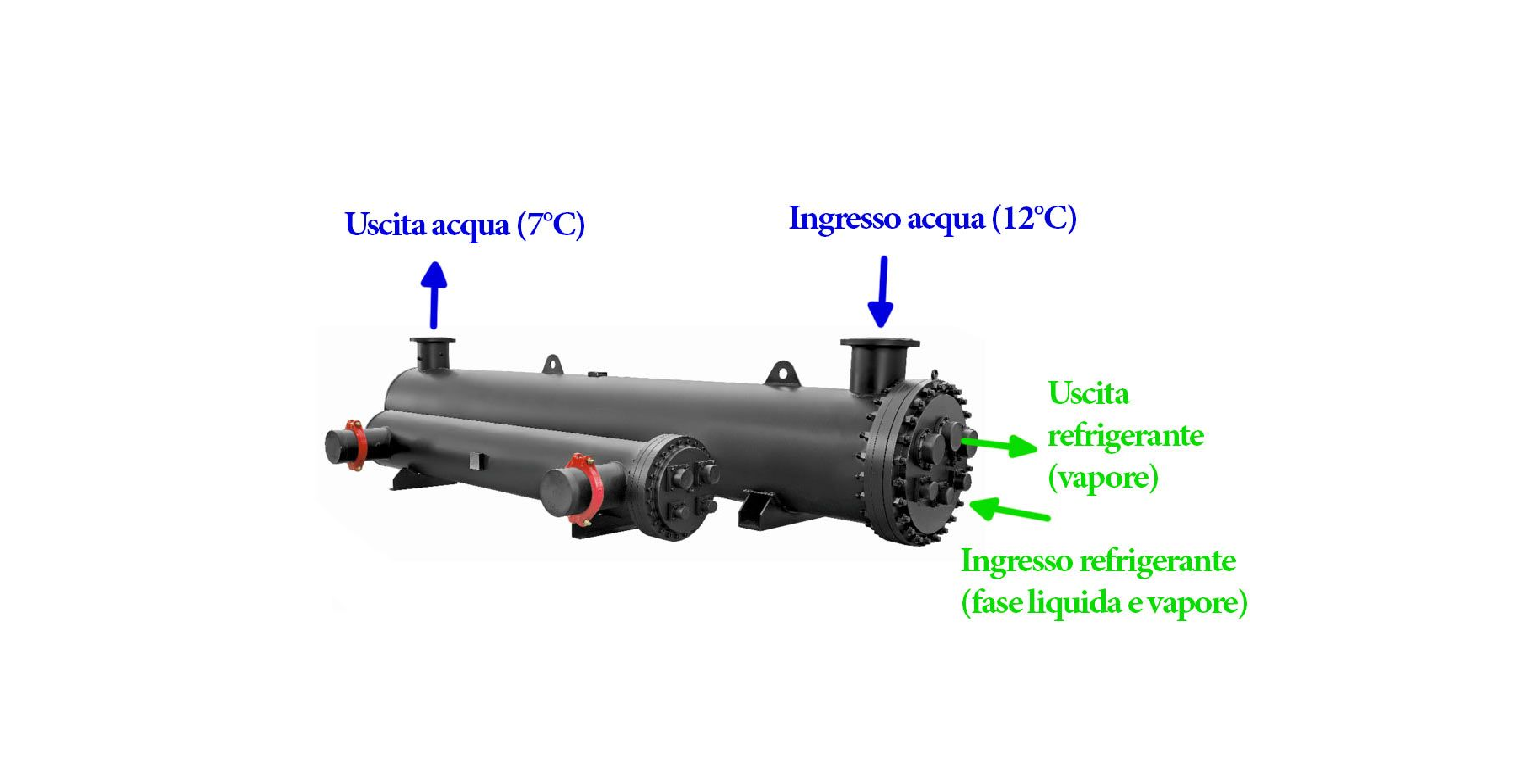

Shell and Tube evaporators

Shell and Tube evaporators LSE - SSE

The main applications of dry-expansion evaporators are the water chilling in air conditioning plants, the liquid or brine solutions cooling in refrigeration plants, the water heating in heat pump systems.

LSE / SSE models are optimized for use with R134a, but can be used with the most common refrigerants; through the selection software and the support of our Technical Department, it will be possible to get the best solution for any working condition.

The Wieland Onda shell & tube compact evaporators have cooling capacity range, at specified standard conditions, from 160 kW till 1600 kW, up to 4 refrigerant circuits.

The tube bundle, directly welded to the shell, is non-removable: the straight tubes configuration allows anyway to clean easily the inner of tubes.

This evaporators can guarantee a better thermal performance through a perfect counter-current flow, and the reduction of by-pass flow, thanks to strict

mechanical tolerances of the components.

Shell and Tube evaporators LPE - MPE - HPE

The main applications of our dry-expansion exchangers are the water, the liquid or brine solutions cooling in refrigeration plants and the hot water productio in heat pumps.

Suitable refrigerants are: HCFCs, HFCs, and others, unless they are compatible with material construction.

The Wieland Onda shell & tube compact exchangers series have cooling capacity range, at specified standard conditions, from about 15

up to 1400 kW with 1 to 4 refrigerant circuits.

Hybrid Film Evaporator

Benefits

Onda has recently developed a new innovative evaporator to respond to an increasing efficiency market demand and a reduced refrigerant charge to balance the continuous refrigerants cost and taxes increase.

The “Hybrid Film“ evaporator combines the benefits of the pool boiling reliable performance and the falling film evaporator low refrigerant charge.

The concept of this innovative heat exchanger has been developed by R&D and validated in Onda’s laboratory with turbo (no oil) and screw compressor (with oil).

The core design belongs to Onda’s IPR and it is patent pending.

The Hybrid Film evaporator new distribution system allows to keep control of the refrigerant liquid around the tubes in all the different working conditions, at full load and at part load as well.

The amount of refrigerant liquid surroundings the tube is also optimized and reduced.

Approach

Part load: when moving < 80% of the load the hybrid lm is performing better with a reduced temperature approach with a positive impact on the chiller IPLV.

Similar performance is also expected with HFO R1234ze. Refrigerant charge reduction : the charge saving vs flooded is in a range of 35 – 40%.

You can download the catalogue in the link below :

https://www.onda-it.com/eng/products/shell-and-tube-heat-exchangers/hybrid-film-evaporator

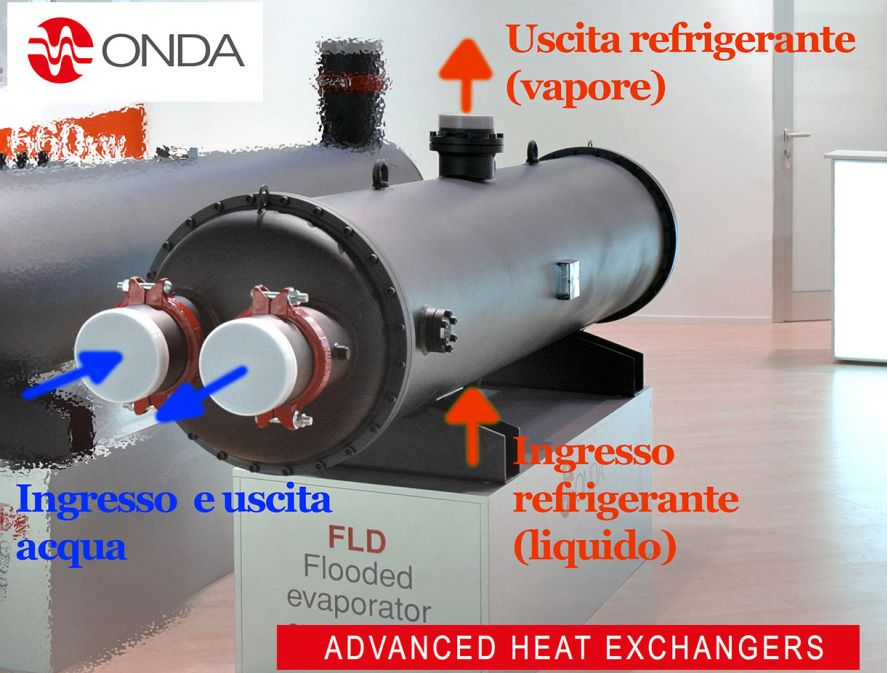

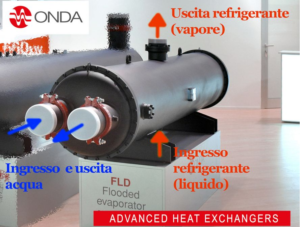

Flooded Evaporators

Flooded Evaporators

In the flooded evaporators, a pool of refrigerant in the shell is submerging the tubes to a set level.

As the refrigeration load varies, a refrigerant-level control acts to maintain the liquid level in the shell.

The refrigerant pool in the shell behaves as a flywheel, allowing the control of the flooded evaporator to successfully track the varying load of a batch process.

More than 7 years of specific experience and continue laboratory tests are combined in the Wieland Onda flooded evaporators, the best flooded evaporator ever.

Designed for high efficiency water chillers in combination with oil-free compressors, they can guarantee an optimal performance even in

presence of screw compressors.

Brazed plate heat exchangers : Evaporation/Condensation/Single phase

Brazed plate heat exchangers: single-phase and two-phase

Plate heat exchangers have the general purpose of heating / cooling process fluids (for example water, oil, glycol, etc.)

In the two-phase field they are used as evaporator or condenser (using refrigerant fluids such as R134a, R1234ze, R410A, etc.) in a vapor compression refrigeration cycle.

In this article we will try to explain in simple way these types of heat exchangers.

In the case of a single-phase process we have two fluids that enter the heat exchanger generating a perfect countercurrent flow, therefore, the hypothetical maximum outlet temperature of both fluids will be equal to the inlet temperature of the opposite fluid.

This could only happen if the exchange area tended to infinity, so in reality this cannot happen.

So let's see an example of a single-phase countercurrent flow, in which the cold fluid (in blue) enters and increases his temperature removing heat from the hot fluid (red) which is going to cool down, decreasing its temperature

In the case of a plate heat exchangers evaporator, in general, the purpose is to cool down a process fluid by evaporating a refrigerant fluid at constant temperature.

By far the most common application is to cool water from 12 ° C to 7 ° C for air conditioning systems.

In this plate heat exchanger, the refrigerant fluid enters in liquid phase at high speed (in reality the inlet vapor quality goes from 0.2 to 0.3) and evaporates through the plate exchanger from the bottom upwards, removing heat from the fluid that flows on the other side.

The last part of the exchanger is used to overheat the already evaporated gas so that there is no return of liquid particles in the compressor to avoid breakage of the compressor itself.

The most important part of this process of evaporation is the correct distribution of the two-phase fluid at the inlet of the heat exchanger.

The target is to introduce the same gas flow rate in every channel of the heat exchanger along all the package of plates.

Onda has patented a distribution system that allows gas to be distributed homogeneously along the entire exchanger.

As we can see in the figure, it can be seen that a correct distribution has a homogeneous overheating zone of the gas (in orange) from the beginning to the end of the exchanger.

If the distribution is not homogeneous we will have areas with more superheated steam and areas with less superheated steam, the operation of the chiller in this case may be unstable.

In the last case of brazed plate heat exchangers condenser, on the other hand, we have a refrigerant fluid in a gaseous state (generally at a high temperature about 60-70 °C) that condense at the expense of a fluid which, on the other side of the exchanger, is heating up.

In general the condensing temperature of the refrigerant is about 40°C and the fluid in the other side goes from 30 to 35°C.

The last part of the exchanger is used to subcooling the liquid condensate by a few degrees, usually 3-4°C.

In this case the superheated gas enters at the top and descends through the exchange plates, condensing until it becomes liquid and exiting at the bottom.

Enrico Golin

Wieland Onda Srl

Shell and Tube Condenser

Shell and Tube Condensers

The main applications of the Shell & Tubes condensers are the condensation of refrigerant gas in the air conditioning and refrigeration plants, and heat recovery.

All refrigerants are suitable, provided they are compatible with the materials used for construction.

In standard conditions shell & tube condensers have an heat capacity between 10 kW and 2 MW.